Delivering innovation to global industry leaders

LENET

Focusing on the R&D, application, and promotion of high-precision positioning technology, we have been recognized as a global leading service provider of 10cm high-precision positioning systems. We offer comprehensive customized services to our partners, providing an integrated location service that combines hardware, software, and algorithms.

- Success Stories 1100+

- Countries and Regions 20+

- Intellectual Property 30+

- Research and Development Experience 10+

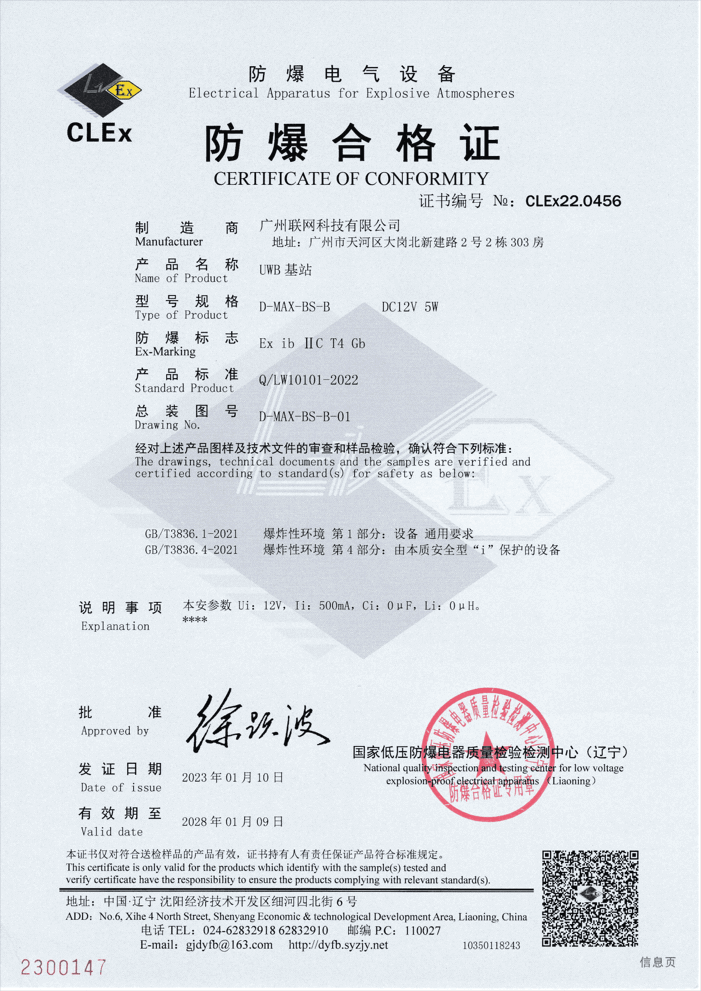

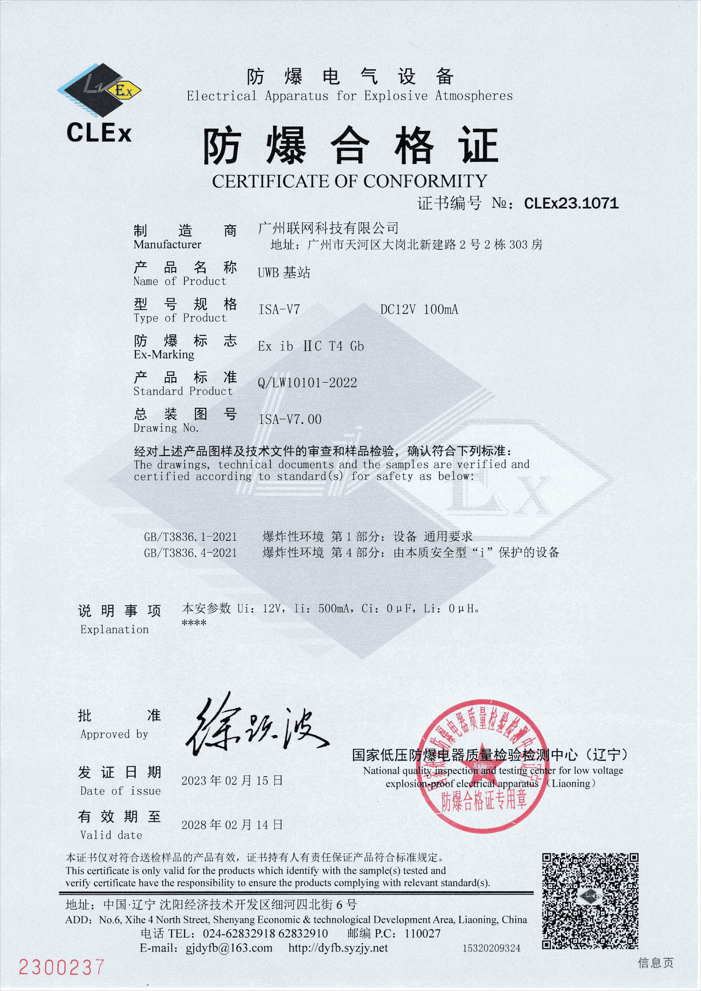

LENET TECHNOLOGY CO.,LTD has been recognized as a global leading provider of 10cm high-precision positioning systems. Proficient in UWB (Ultra-Wideband) positioning, Connected Technology is always committed to offering comprehensive customized services to users, including integrated positioning hardware and software. Connected Technology is dedicated to contributing to the vigorous development of the Internet of Things and Industry 4.0. The company has: 5 years of experience in developing UWB positioning products and customized development platforms; Over 10 industry applications, including smart manufacturing, mining construction safety, petrochemicals, tunnel construction safety, intelligent warehousing, smart construction sites, and logistics warehousing; More than 20 application scenarios; Over 20 national patents and software copyrights; Certification as a National High-tech Enterprise; Some products have passed the intrinsic safety explosion-proof certification.

Real-time indoor and outdoor personnel and vehicle positioning

Forklift Tracking and Monitoring

Measure and enhance the efficiency of your forklift fleet. Track and monitor your forklifts, tractors, and other material handling equipment. Implement anti-collision measures for forklifts.

Real-time personnel tracking

The positioning system can help organizations enhance the safety of their team members, reduce the time required for mustering and rescue operations, improve security, and streamline location-based work hour reconciliation, thereby safeguarding the well-being of the team.

Asset Operation and Positioning

The goal of tracking assets is to maximize asset utilization, prevent asset misuse, and optimize their role in all processes.

Improve production efficiency

Accurately locate the real-time positions of people, vehicles, and objects, and combine this with services such as trajectory tracking, labor hour statistics, area counting, and electronic fencing to enhance work efficiency, assist in improving factory material management, optimize processes, and elevate the management level of smart factories.

Personnel and Vehicle Route Analysis

Personnel and Vehicle Route Analysis allows you to gain real-time insights into the status of your fleet and personnel activities, and precisely track their historical locations to better improve processes.

Business Digital Twinning

Digital Twin technology enables you to visualize data and processes within your facility environment, allowing you to better understand any changes and see their impacts.

Customer Case Studies

- Logistics and Warehousing

- Digital Factory

- Forklift Anti-collision

- Petroleum and Chemical Industry

- Industry 4.0

Logistics and Warehousing

The UWB (Ultra-Wideband) logistics and warehousing system utilizes centimeter-level positioning technology to track goods, forklifts, and personnel in real-time, enabling precise visualization within the warehouse. The system automates operations such as inbound, outbound, and inventory counting, optimizing processes and improving efficiency. The intelligent route planning function provides optimal paths for forklifts and personnel, reducing unnecessary movements. Electronic fencing and safety alert functions ensure warehouse security by preventing abnormal activities. The data analysis function generates visual reports to help managers optimize warehouse management. The UWB logistics and warehousing system significantly improves efficiency, reduces errors, optimizes management, and enhances security. It is widely used in e-commerce, retail, manufacturing, pharmaceuticals, and other industries, suitable for various types of warehouses and distribution centers. As UWB technology continues to evolve, the system will become more intelligent and integrated, offering more efficient, precise, and secure warehousing management solutions for the logistics industry and driving the industry towards a smarter future.

Read Customer Case

Lexus 4S Store

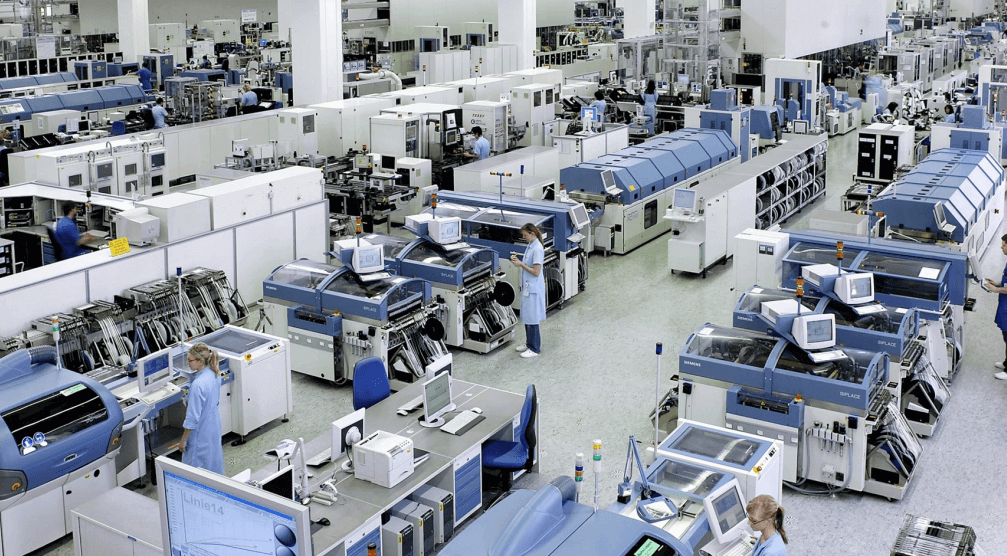

The UWB (Ultra-Wideband) digital factory system utilizes centimeter-level positioning technology to track personnel, vehicles, materials, and equipment in real-time, enabling precise visualization of production elements within the factory. The system optimizes production processes, dynamically adjusts production plans, and significantly improves efficiency. Electronic fencing and safety alert functions ensure factory security by preventing abnormal activities. The data analysis function provides visual reports to help managers optimize operational decisions. The UWB digital factory system is widely used in automotive, electronics, machinery, chemical, and other manufacturing industries, suitable for various production workshops and warehouses. The system improves efficiency, ensures safety, optimizes management, and reduces costs, driving the digital transformation of the manufacturing industry. As UWB technology continues to evolve, the system will become more intelligent and integrated, offering more efficient, safe, and intelligent production solutions for the manufacturing industry and helping the sector step into a new era of smart manufacturing.

Read Customer Case

Midea Water Purification Plant

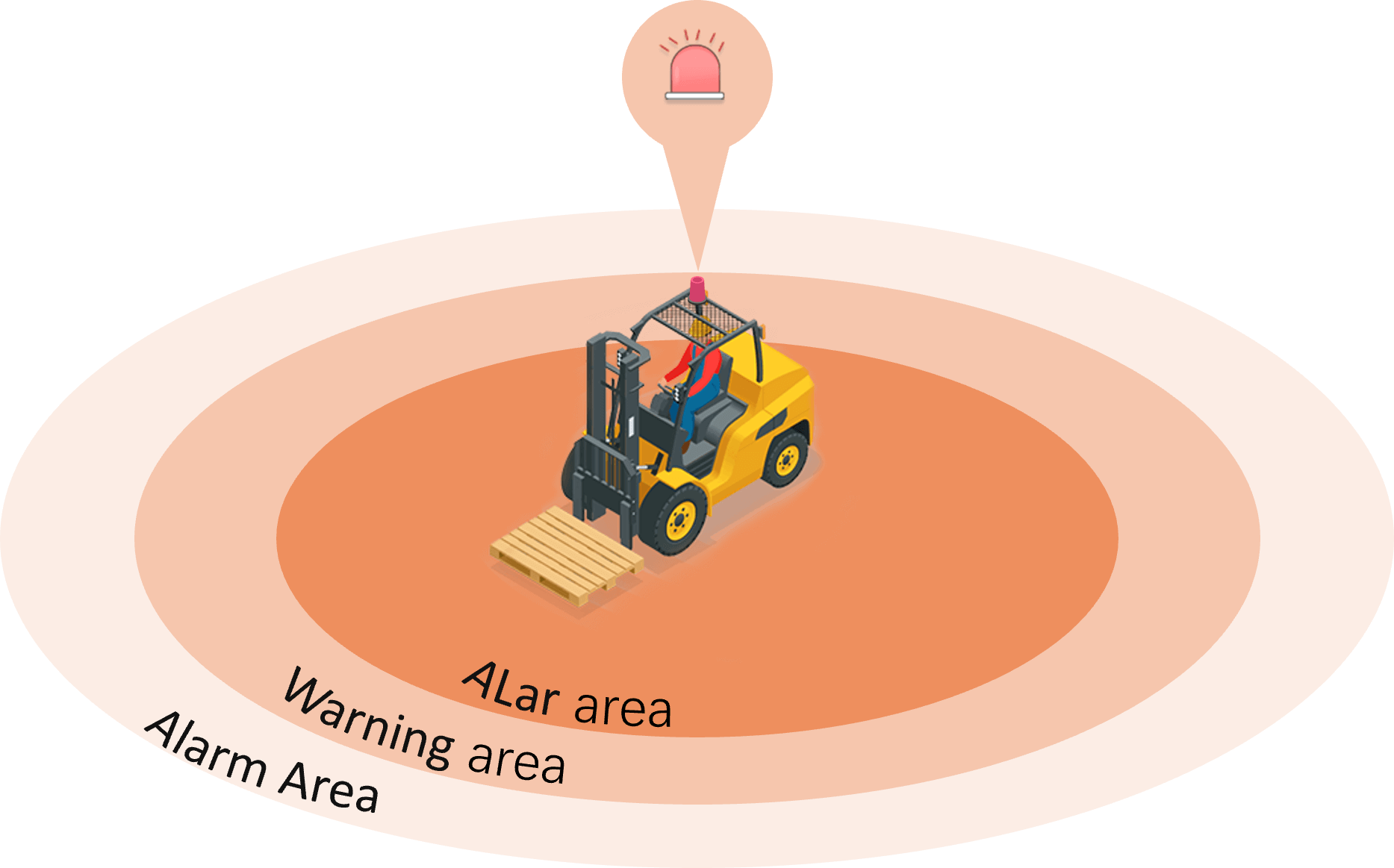

The UWB (Ultra-Wideband) forklift anti-collision system utilizes centimeter-level positioning technology to monitor the distance and position between forklifts, personnel, equipment, and other forklifts in real-time, effectively preventing collision accidents. The system alerts operators through audio and visual alarms, automatic deceleration, or emergency braking, and takes evasive measures to ensure operational safety. Additionally, the system records operational data, providing a basis for accident analysis and safety management. The UWB forklift anti-collision system is suitable for various warehouses, workshops, logistics centers, and other scenarios. It significantly enhances the safety of forklift operations, reduces the accident rate, and lowers corporate operational risks. As UWB technology continues to evolve, the system will become more intelligent and precise, offering more reliable protection for industrial safety.

Read Customer Case

Chongqing Southwest Oilfield Purification Plant

The UWB (Ultra-Wideband) petrochemical system utilizes centimeter-level positioning technology to track the locations of personnel, vehicles, and equipment in real-time, enhancing the safety and operational efficiency of petrochemical plants. The system prevents accidents such as unauthorized entry into hazardous areas and equipment collisions through electronic fencing, safety alerts, and emergency distress functions, ensuring personnel safety. Additionally, the system optimizes inspection routes, material scheduling, and equipment management, improving work efficiency and reducing operational costs. The UWB petrochemical system is suitable for refineries, chemical plants, oil storage areas, and other scenarios, providing precise positioning and intelligent management solutions for high-risk working environments. As UWB technology continues to evolve, the system will become more intelligent and integrated, helping the petrochemical industry achieve safe production and digital transformation.

Read Customer Case

Hebei Mine

The UWB (Ultra-Wideband) Industry 4.0 system utilizes centimeter-level positioning technology to track the locations of miners, vehicles, and equipment in real-time, enhancing mine safety and production efficiency. The system prevents accidents such as unauthorized entry into hazardous areas and equipment collisions through electronic fencing, safety alerts, and emergency distress functions, ensuring miner safety. Additionally, the system optimizes personnel scheduling, material management, and equipment monitoring, improving operational efficiency and reducing costs. The UWB Industry 4.0 system is suitable for underground mines, open-pit mines, and other complex environments, providing precise positioning and intelligent management solutions for high-risk working scenarios. As UWB technology continues to evolve, the system will become more intelligent and integrated, helping the mining industry achieve safe production and digital transformation, and driving the sector towards a smarter future.

Read Customer CaseReal-time Location System Solutions

UWB Base Stations

The UWB high-precision positioning platform can track personnel, vehicles, and assets. It monitors operations in real-time, ensures personnel safety, collects data, and analyzes processes and management to help businesses improve production efficiency and optimize all workflows.

UWB Tags

The UWB high-precision positioning platform can track personnel, vehicles, and assets. It monitors operations in real-time, ensures personnel safety, collects data, and analyzes processes and management to help businesses improve production efficiency and optimize all workflows.

GalaxyTrack Platform

The UWB high-precision positioning platform can track personnel, vehicles, and assets. It monitors operations in real-time, ensures personnel safety, collects data, and analyzes processes and management to help businesses improve production efficiency and optimize all workflows. It also provides real-time location tracking, trajectory playback, various positioning data analysis, forklift collision prevention, and industrial digital twin applications.

_00.a987d70c.png)

_00.e81169b6.png)